Our Products and Services

Pioneering Progress, Empowering Industries

Driven by Excellence, Shaping Tomorrow’s Solutions

Real ID Consultant – DIMULTI Indonesia

How We Work

We are proud to have served

Our Top Clients

The term “Manufacturer” refers to the owner of the Brand and Product Design. Besides, Manufacturer also owns any intellectual rights related to the product. Manufacturer can be the factory. But in some cases, depending on the business model, manufacturer is not always the factory.

Let’s take this as an example; the brand and product design owner is a private company based in Canada. To produce the ICT product designed by this Canadian company, the company owns and manages a factory which is located in China. It can be their own company, or a third-party factory through subcontracting process. Therefore, although the product is designed in Canada, but it is manufactured in China, which makes the product is labelled as “Made in China”. That’s the example where manufacturer and factory are separated company.

In contrast to that, manufacturer and factory can be the same company. Manufacturer office can be located in the same location as the factory. And they are probably under the same company too. So, besides designing the product, this company also manufacturing the product at the same site. That is the example where Manufacturer and Factory are the same company.

Either way, manufacturer is the one who has the product design and own the brands. Therefore, before sending the product out from their manufacturing site, they need to make sure that the products comply with the regulatory standard of where it will be marketed. Prior to the distribution and sales, the product must be adjusted to be aligned with the applied standards. That’s why it is important for the manufacturers to obtain compliance certificate prior to the product shipping.

Factory is the place where ICT products are being manufactured. don’t be confused by the term “Factory” or “Manufacturer” like many people do. Although factory can refer to the same entity as the manufacturer, in some cases, factory is a different entity from the Manufacturer.

Factory can be the same entity as the manufacturer if factory doesn’t only manufacture the products, but they also design the product, owns the brand, and are entitled to any intellectual properties of the product. In other words, they do not manufacture products based on orders from another company, but they design and manufacture their own products in the same site.

On the other hand, factory can be a different entity from the manufacturer. This is the common practice in the product manufacturing process. This usually happens when manufacturer only acts as the brand holder, and product design owner. They do not manufacture the product in their office due to the lack of manufacturing and testing equipment. So, they manufacture the product in somewhere else. And by “somewhere else”, it means in their own factory which is located in the different area or even in the different countries, or in the third-party factory through subcontracting process.

In manufacturing ICT products, a factory, whether it is managed by the manufacturer or it is a third-party factory, must pay attention at one thing: compliance. Usually, manufacturer orders a product to be marketed to a certain region which has specific standard. To comply with this standard, tailored manufacturing process is obviously needed. Therefore, prior to the manufacturing or distribution activity, it is important for the factory to pay attention at region’s specific standard. Therefore, when manufacturer sends the product to the market, the product won’t face any rejection due to the failure to meet the applied standard.

Importer is the entity who imports the product from overseas location. In product supply chain, they are the ones that will deal with customs clearance process. During this process, importers are requested to submit several documentations as the mandatory requirements to release the products. The list of documents is different, depending on the type of product that will be released.

In some cases, compliance certificates are within the list of required documents for clearance process. That’s why, prior to the import process, importer will check the availability of this compliance certificate. Because if the certificate is not available, then clearance is not possible to be continued.

Whereas Distributor, it is the entity who has distribution rights of the product in Indonesia. After the importation process is finished by the importer, distributor will make sure that all compliance requirements are fulfilled by the product. This must be ensured before they distribute the product to their distribution area.

Besides distributing the product, distributor usually also hold the warranty of the product as well as manage the service centre. Therefore, whenever there’s claim or complains from the buyer, usually these will be forwarded to distributor to get replacement or solution. Moreover, distributor is also responsible for the product safety and compliance. Therefore, if authority finds any danger, interference, or harm caused by the product, it is the distributor who will be held responsible.

Distributor and Importer can be the same company. This means that the company does both product import and distribution. However, in the bigger industries such as automotive, the business model is more complex. Distributor and importer can be different companies.

Either way, prior to the import and distribution process, both distributor and importer must pay attention to the compliance aspect of the products that they are about to sell. Although usually the compliance aspect has been taken care by the manufacturer, both distributor and importer must take part in ensuring that the compliance certificate is well obtained, and suitable with the target country.

International Laboratories are basically test laboratories located outside of Indonesia. Some example of well-known international laboratories are Bureau Veritas (BV), Underwriters Laboratory (UL), Technischer Überwachungsverein (TUV), Hyundai Calibration & Certification Technologies (HCT), Societe Generale de Surveillance (SGS), Dekra, Nemko, and many more.

These laboratories big company group which manages multiple branches around the world. Each branch is accredited by accreditation bodies to perform particular test standard according to their capabilities.

Prior to the product sales and distribution, usually manufacturers, factories, or product owners will approach these laboratories to perform testing which is relevant to the product. This test is required to obtain compliance certificate which is essential when accessing global market.

Therefore, when contacting these labs, usually they will be redirected to Global Market Access (GMA) team which will suggest manufacturers, factories, or product owners the specialized testing process according to the target market.

Besides giving advise related to the market access, GMA team is also responsible to do regulatory compliance research in the countries which becomes target market. In each country, usually they will source local consultant partner, either their own-consultant firm or third-party consultant, to conduct some activities related to the obtaining compliance certificate.

Some activities like discussing with local authorities, conducting local test when required, submitting application documents, etc. are usually conducted through their consultant partner. So at the end, compliance certificate from target country can be obtained without the present of Lab’s GMA team in the target country.

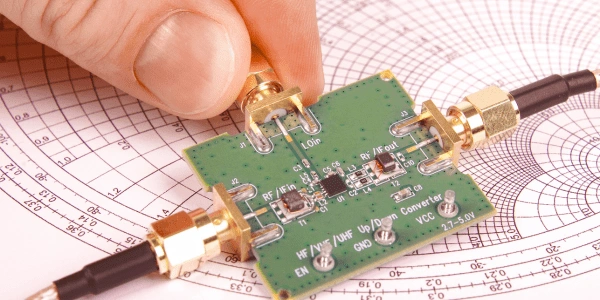

Product Compliance Consultant is a consulting company that’s specialized its services on providing consultation related to the product compliance. Commonly, it is also called as Global Market Access Consultant. Besides providing consultation, usually the service also includes and activities required to obtain compliance certificate such as doing local test when required, checking required document, discussing with the authority, and any effort required for the certificate to issue.

Product Compliance Consultants offer their service to manufacturers, testing laboratories, importer, distributors, or factory who wants to sell their product to Global market. Some services covered by Product Compliance Consultants such as doing regulatory research toward specific target market, doing market access research including some topics such as compliance requirements and procedure. Moreover, they also conduct compliance certification process on behalf of the manufacturer, offer the better tailored solution for more effective and efficient compliance certification process, and many more.

Some consultants that have better resource, they own test equipment. So, this consultant can also do retest in their office to make sure the product has complied with the regulatory standard before it is sent to the test lab for official testing. So, in order to perform this test, it is important for the consultants to understand regulatory standard of the countries they are covering.